In recent decades, the constant worldwide increase in air traffic has led to the development of large-fuselage aircraft such as the Airbus A380 and the Boeing B777 and B747-8. These are all large-capacity aircraft with the autonomy to fly long haul, and are therefore much larger and heavier than previous models. This has led to changes in the management, design and maintenance of airport infrastructure, both landside and airside. Airports have had to enlarge their terminals and access road in order to be able to accommodate more passengers, and have also had to increase the dimensions of their runways, taxiways and aircraft parking aprons.

Of all airport installations, the airfield is of critical importance, as it is where aircraft continuously taxi, take off, land and park. In many cases, they are in use 24 hours a day. For this reason, the International Civil Aviation Organization (ICAO) considers preventive maintenance to be of great importance, as the failure to correctly undertake these actions incurs additional costs, such as traffic restrictions or closures in order to carry out the necessary works, in addition to the cost of the repair works themselves.

Currently, the majority of airports find themselves handle more intense levels of traffic than they were designed for. As a result, the pavement deteriorates due to the loads produced by aircraft. This is then further exaggerated by exposure to the elements. In order to maintain operational safety, managers have to double their maintenance efforts.

Ineco has designed Gestrol, an application that provides the airport management with all the necessary information about the condition and evolution of the pavement

In any case, airfield pavements are dynamic in nature: their properties will change with the passage of time and the amount of airport traffic. Therefore, once it has reached the end of its useful life, usually around 20 years, new design, works and exploitation will be necessary. This cycle will not need to be applied to the entire pavement, rather only in the areas where it is necessary.

Airport managements are not usually aware of the overall conditions of the airfield pavement. For this reason, when a problem is detected, an immediate solution is required, generating unforeseen costs. Ineco has designed Gestrol, an application that provides the airport management with all the necessary information about the condition and evolution of the pavement, in such a way that they can anticipate future problems and possible solutions.

In addition to maintaining the minimum levels demanded by the international civil aviation regulations, the tool applies the quality levels that each manager chooses to implement. The application directly connects the manager to an engineer over the Internet, so that any issue may be resolved practically in real time.

When aviation was in its infancy, planes used to take off and land on earth or grass airfields. With the increase in size and weight of planes, airfield pavements also evolved and became more specialised in order to be able to bear growing loads and ever-intensifying usage. Currently, there are two main types of airport pavement: rigid and flexible. Both are made up of various layers. In rigid pavement, the top layer is made up of concrete slabs, while in flexible ones, asphalt materials are used. The lower layers absorb loads, reinforcing the earth’s load bearing capacity, and sometimes also help drainage. They are made up of different materials and may include the addition of a stabilising or binding ingredient to increase resistance.

Pavements are designed to withstand any weather conditions, in accordance with the loads determined in structural calculations. If loads or usage levels (or both) are greater than those for which it was designed, larger deformations will be produced, affecting the different layers and thus shortening the lifespan of the pavement. When measuring the deformations, an indicator called PCN (Pavement Classification Number) is obtained; this indicates the resistance to unrestricted use. This indicator is linked with another value known as ACN (Aircraft Classification Number) which indicates the relative effect of an aircraft on the pavement for a particular category of terrain. If this second value is less than or equal to the PCN, the pavement will be able to withstand operations without restriction.

Airfield pavements are designed to withstand any weather conditions in accordance with determined loads

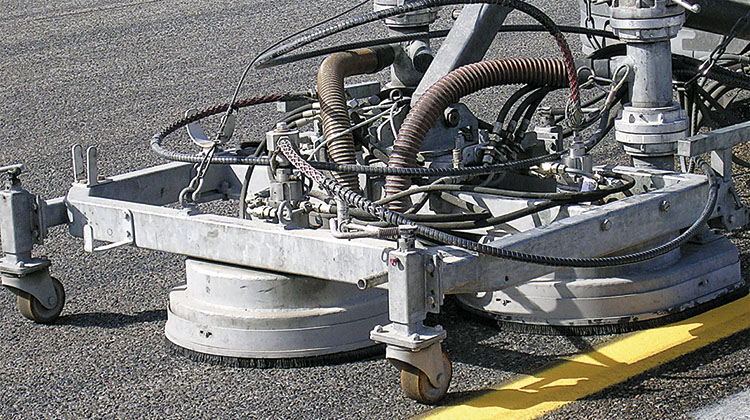

As well as the load bearing capacity, other factors that determine the conditions of the pavement are the coefficient of friction and the surface texture. Friction between the surface of the runway and the tyres of the landing gear should be sufficient to ensure the maximum braking effectiveness, making this a factor which directly affects safety. According to the ICAO’s Airport Services Manual, the frequency of measurements must increase with the number of landings that occur: for less than 150 daily landings, once a year; between 150 and 210 landings, twice a year; and for more than 210 landings, three times annually.

The texture of the runway is crucial when it is wet, given that if the tyres lose contact with the surface of the runway, hydroplaning can occur; this in turn leads to the loss of control of braking and the steering of the aircraft.Slippery textures can be caused by the accumulation of rubber from the tyres of the landing gear or by wear from traffic. There are various measurement methods to determine whether the texture is suitable and what actions should be taken (clean-up of the rubber, screeding, etc.) if this is not the case.

All of these factors are reviewed and monitored through a Maintenance Plan. The information gathered through the various tests and studies is collected in a database, which is updated with the results of periodic assessments and any preventive or corrective work, as well as any possible change to traffic levels.

Advantages of the Gestrol tool

- A powerful database which records measurements for various parameters of the pavement: construction dates, dates when work was carried out, pavement sections, number of operations and aircraft models, etc., as well as the results of studies undertaken for each of the assessments.

- Historical information regarding the overall condition of the pavement.

- The recommended procedures to maximise the lifespan of the pavement at minimal cost.

- Analysis of the evolution of the lifespan of the pavement according to its conditions, and any work that may be necessary in the future, as well as any variation in aircraft operations.

- Studies into the overloading of the pavement, as well as possible screeds that may meet future requirements.

Types of periodic assessment

- Assessment of the coefficient of friction and the surface texture of the runway: this consists in determining the resistance of the pavement surface to the movement of aircraft, and whether it provides the optimum level of braking effectiveness.

- Assessment of load bearing capacity: determines the level of resistance of the different layers making up the pavement. The PCN (Pavement Classification Number) is obtained from this study.

- Assessment of the PCI (Pavement Condition Index): this is a numerical indicator that evaluates the quality of the surface and catalogues the different types of deterioration present in both flexible and rigid pavements and reveals superficial or structural defects.

- Assessment of surface regularity: this determines the comfort level of rolling aircraft, avoiding any possible ricochets, wobbles or vibrations that could make manoeuvring the aircraft on the ground more difficult.