Since time immemorial, building new structures has always been more glamorous than maintaining and improving existing ones. Although today’s construction materials are diverse, high quality and more sophisticated than those of times past, they also require more maintenance than –for example– the iconic stone structures built by the Romans.

In order to define a suitable maintenance programme that will maximise a structure’s service life, which begins as soon as the construction work has come to an end, it is necessary to carry out a study. First, it is vital that you obtain data on the real condition of the structure. To do this, you need to go out into the field, visit the structure in question and perform an inspection. In Spain, there are specific guides and instructions that define the different types of inspection. Is the case, for example, the Instruction for the Technical Inspection of Railway Bridges (ITPF-05), which defines three types of inspection: basic, main and special. There are similar documents for other types of structures.

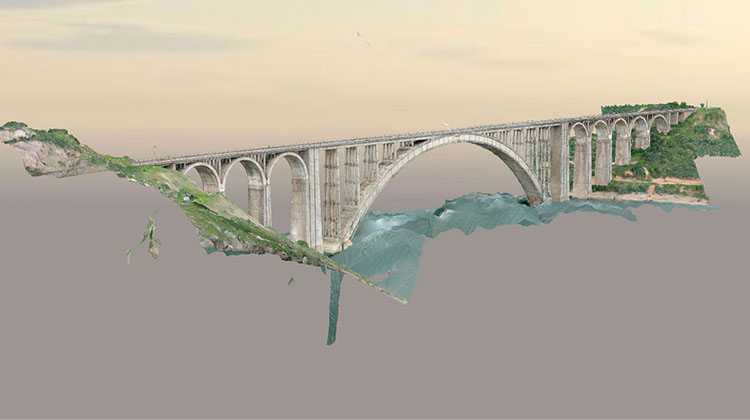

3D model of the Martín Gil viaduct, created using photogrammetry. / INFOGRAPHIC_INECO

These inspections are visual and the information obtained regarding the functional condition and durability of the structure depends, in large part, on the skills and capacities of the inspector. In the university environment, the focus on new construction has resulted in a lack of learning and knowledge with regard to how existing structures behave over time. This, combined with other factors, makes the assessment process more complex.

When it was built, the Mattín Gil Viaduct on the Zamora-A Coruña line boasted the world’s longest concrete arch, measuring 192.4 metres across the central span

Examples of these other factors include the extremely wide range of structural types and materials (concrete, steel, hybrid, stone, composite, etc.) and the many different pathologies generated by mechanical, chemical or physical causes. In addition to these factors, there is also the fact that the majority of structures are not designed to be inspected; many of their elements are hidden or difficult to access. Another of the inspector’s enemies is adverse weather conditions, which can make outdoor work very complicated.

Ineco started to carry out inspections of railway bridges in the 1990s. It has been a member of the Association for the Repair, Reinforcement and Protection of Concrete (ARPHO) since 2010 (when the Association was created); and a member of the European Association for Construction Repair, Reinforcement and Protection (ACRP) since 2020.

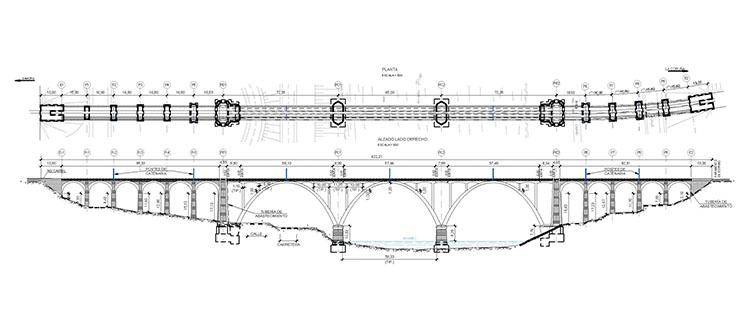

Ground plan and elevation of the reinforcement works for the viaduct over the River Miño in Ourense (AVE Madrid-Galicia). / PLAN_INECO

Today, Ineco’s structural inspection specialists not only provide services to external clients, but also work on a cross-departmental basis within the company, helping all of the different units

–including those specialising in airports, railways and roads– to perform analyses on all types of structure: from bridges and stations to airport terminals and port facilities. The work is usually carried out in two stages: a field inspection, which often includes a series of tests; and an office-based stage, in which the inspection report and plans for structural retrofitting and strengthening are prepared.

Drafting the design project and carrying out the construction work only marks the start of a structure’s service life, although it is a very important stage that creates the base for long-term functionality and durability. However, no structure can exist forever. With a well-defined plan, proper execution with suitable materials and strict supervision during construction, plus preventive and corrective maintenance throughout the structure’s service life, it is possible to reach an age of more than 100 years. However, whether modern buildings can match the longevity of Roman structures remains to be seen!

NOTABLE PROJECTS

Some of the most recent projects include:

- Treatment of infrastructure elements (bridges, tunnels and earthworks) on the Monforte-Ourense-Lugo section. This section, which is nearly 110 kilometres long, is divided into 10 multidisciplinary projects, including track, overheadline and installations. Since 2018, more than 200 people have worked on these projects.

- Reinforcement of the viaduct over the River Miño in Ourense (AVE Madrid-Galicia). This project was carried out 2018 and involved the specification of reinforcement works for the deck section using composite materials (carbon fibre).This historic viaduct is over 400 metres long, incorporating three central 60-metre arches and a total of 14 spans. Prior to defining the actions to renovate and reinforce the structure, Ineco carried out a drone inspection.

- Renovation of the Martín Gil viaduct on the Zamora-A Coruña line. When it was built, this unique viaduct boasted the world’s longest concrete arch, measuring 192.4 metres across the central span. Ineco inspected the viaduct using a drone equipped with both a conventional camera and LiDAR system.

- Study of crown wall pathologies in the Levante breakwater, port of Málaga. Ineco inspected the entire crown wall –a reinforced concrete structure some 1,200 metres long– and drew up a corrosion report. This project was carried out in collaboration with the Eduardo Torroja Institute, part of the Spanish National Research Council (CSIC).

RESEARCH INTO “SMART” BRIDGES

Technological advancements have opened up new possibilities for structural inspection. Ineco, along with the universities of Córdoba and Granada, are part of the consortium for the Smart Bridges project, which over the next three years will explore how the maintenance of railway bridges can be improved using smart technologies. This was one of the projects selected during the call for applications organised by the State Research Agency, which reports to the Spanish Ministry of Science and Innovation.

At present, the methodologies for extending the service life of bridges via structural health monitoring (SHM) are still at an early stage of development. The project will explore the development and application of these SHM methodologies, including the use of smart sensors, achieving energy independence for the longterm monitoring system, and using data to make structural prognoses and maintenance-related decisions. In terms of use cases, a number of key railway bridges in Spain’s high-speed network will be identified and their original designs compared to their current load scenarios, with a view to developing an SHM system. This will make it possible to improve the bridges’ safety systems while reducing their operating and maintenance costs.