The Arid Lap project is financed by the Centre for the Development of Industrial Technology (CDTI), a Spanish public institution, through the Feder-Innterconecta Andalucía 2013 Programme. As suggested by the title –“Minimizing the effects of extreme climates on high-performance rail infrastructures in arid zones”– the aim is to develop technological solutions to minimize the negative impact of the meteorological conditions particular to arid zones on the operation of high-performance rail lines. The project focuses on the impact of sand (both airborne and suspended), and of high-temperature gradients and their consequences for rails and overhead line.

In 2013 and 2014, the universities of Granada, Seville and Madrid, the region of Andalusia, in the south of Spain, and the Málaga Rail Technology Centre all served as testing ground for trials with drones, temperature sensors, sand traps, weather stations, measuring systems, sand containment barriers and a large range of innovation projects.

Analysis of the impact of the environment on rail infrastructures in countries with arid climates showed that wind and suspended sand, as well as extreme temperature gradients, may prevent the line from functioning correctly, on account of abrasion, erosion or the accumulation of sand on the tracks, the wearing down of materials, etc. With a view to tackling these issues, the committee has focused on developing technology to predict and pre-empt the influence of weather conditions on the infrastructure and rolling stock, so that there is sufficient time in advance to take countermeasures.

Ineco participated in this project in consortium with the companies Adif, Elecnor, Deimos, Abengoa, Nervados, OHL and Win Inertia, working collaboratively together

The project’s results will take the form of technical scientific knowledge, which will pave the way for new engineering services and methods on the market for predicting adverse weather conditions and quantifying them when constructing infrastructures in arid environments. Adapting these services to arid conditions will allow for new systems and design recommendations. In short, this will make it possible to optimize the design, construction and maintenance of elements such as rails, railway platforms, catenaries, ballasts, telecommunication systems and security systems.

Teamwork

Ineco participated in this project in consortium with the companies Adif, Elecnor Deimos, Abengoa, Nervados, OHL and Win Intertia, working collaboratively together whilst simultaneously focusing their own research on a specific area. It also collaborated with the project University of Granada, the CSIC´s Experimental Station of arid zones, the University of Seville’s Research Foundation, the Complutense University of Madrid, the Andalusian Association for Research and Industrial Cooperation and the Andalusian Foundation for Aerospace Development.

Ineco, Elecnor Deimos and Adif, together with Fada-Catec, have worked on three campaigns flying drones to determine their usefulness in detecting sand, rocks and obstacles on the track, anomalies in catenary cable compensation, cracks, water yields and landslides. Studies have also been conducted on: whether UAV (Unmanned aerial vehicle, or drone) flights are compatible with high-speed environments, inspecting limited-access viaducts, and generating orthophoto maps and high-resolution digital models of the terrain.

In terms of the impact of the environment on the infrastructure, Ineco and OHL have analysed the geomorphological risks and ecological processes in desert areas. Ineco and Adif have analysed the lines in operation, their problems and the solutions that have been adopted. Ineco and Abengoa have carried out a study on the requirements and responses to take into account for the track devices in the face of adverse weather conditions in desert areas.

Seven companies, 14 R&D projects

1. Ineco: Forecasting models, drones and web platform

Ineco, together with the University of Granada, has developed a mesoscale meteorological model for forecasting wind and aeolian sand transport. It is essentially an application that, at least 48 hours in advance, is able to communicate the wind’s direction and intensity at specific relevant locations, as well as the levels of airborne sand associated with the wind levels at these locations. To this end, the company has installed a weather station and sand traps, to be used to calibrate the model, at the Doñana Biological Reserve dune field in Huelva.

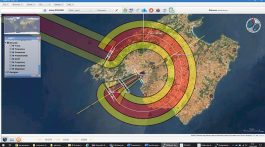

Ineco also developed the web platform MARTE, bringing together all results from the various activities that form Arid Lap. In this way, MARTE manages monitoring information, alarms and predictions. The tool manages and processes data registered by the sensors on the Córdoba-Málaga high-speed rail line, specifically at Málaga station (sensors to detect sand build-up, rail temperature, rail stress, overhead line temperature and stress), as well as at the Doñana weather station. Furthermore, alerts are sent when the sensor thresholds are exceeded. There is a unit for spatial visualization and integrating the satellite, drone and aerosol (suspended particulate matter) images generated during the project.

2. Abengoa: Sensor and alert systems. Protections in sensitive elements of the infrastructure

As leader of the consortium, Abengoa actively participated throughout the project, focusing on studying the electrical insulator distances in environments with high levels of sand/dust in the air, and on developing sensor system methods to monitor and supervise the state of rails and overhead line in real time. Their aim is to send alerts when the values exceed those which limit operability and safety.

The technological development team for the department of Railway Engineering at the Rail Technology Centre (CTF) in Málaga has also conducted research on systems which prevent sand from accumulating on the junctions. These can be elevated structures which replace the ballast, or wind acceleration structures. They are designed to protect the hinged sections, and the greasy sections of elements that require lubrication in the overhead contact line, from the negative effects of a build-up of sand, extreme changes in temperature and water condensation. Lastly, they also designed new mechanisms for protecting elements of the compensation system for pulleys and counterweights against arid environments.

3. Win Inertia: Electronic as a solution. Sand sensors and communications

This Andalusian company has developed a sand build-up sensor, which measures both the weight and height of the accumulated sand. They have also simultaneously developed a concentrator system, which collects information in situ from the sensors (both the Abengoa ones and the Win Inertia ones), and then sends it to MARTE to be managed.

4. Elecnor Deimos: Aerospace technology for railways

They have focused their involvement on applying new aerospace technologies. They primarily developed on three lines, using satellite images to identify and quantify adverse conditions in arid zones for the first line, as well as identifying the changes that might arise, as concentrated aerosol images. These allowed them to evaluate their use in studying the risks associated with dust in the infrastructure in advance, or high-resolution Deimos-2 images in order to estimate the technical viability of using algorithms to detect changes to pinpoint the spread of sand and dust.

They also used images from drones to achieve sub-centimetre resolution, which makes it possible to semi-automatically detect, from the difference in height, the rock fall on the track. Lastly, Elecnor Deimos has developed an infrastructure for processing, storing, distributing and visualizing images from satellites, UAVs and related products based in cloud technologies, integrated with the control application MARTE, which was developed during the project.

5. OHL: Ecological Recovery and containment systems

OHL and Nevados jointly developed a containment system which produces a “trampoline” effect, concentring and projecting the natural flow of air with suspended sand around the sides of the rail infrastructure. Using 2D simulations and trials in wind tunnels, they have come up with a design which prevents the sand from moving forwards (with wind speeds below 15 m/s), or throws away and above the track, owing to its aerodynamic design (speeds greater than 15 m/s). At the same time, OHL have carried out a critical analysis on applying ecological recovery to the railway environment in arid areas.

6. Nervados: Concrete know how. Prefabricated and personalized

Nervados has taken on the challenge of optimizing the design part and modelling of the prefabricated concrete barrier that impairs performance, as well as the manufacturing, transportation and concrete spreading processes. They have researched the need for concrete which is resistant to erosion and extreme temperatures, both when being manufactured and when put to use. At their facilities, they have carried out the entire prefabricated concrete piece project, with the exception of manufacturing the moulds.

7. Adif: Validating new technologies, radar sounding with GPR and drones for railways

Adif, meanwhile, has been responsible for the integration and validation, in a high-speed environment, all systems developed by the other partner companies, establishing the requirements of each development and installing sensors at María Zambrano Station and MARTE application in the Rail Technology Centre, both in Málaga, and facilitated the use of its infrastructure for testing drones for railway applications. Furthermore, they have carried out tests to detect the ballast contamination level using a Ground Penetrating Radar (GPR), which demonstrated this non-destructive sounding technique to be a good solution.